Mining

Mining Industry Products

MCC Mining products are tough, proven and preferred. With tight tolerance control and company owned manufacturing facilities, products are guaranteed to interchange.

MCC Claw Couplings

Designed specifically for the Australian Mining Industry, the MCC Claw Couplings are available in A Type, S Type & B Type (Universal) head patterns.

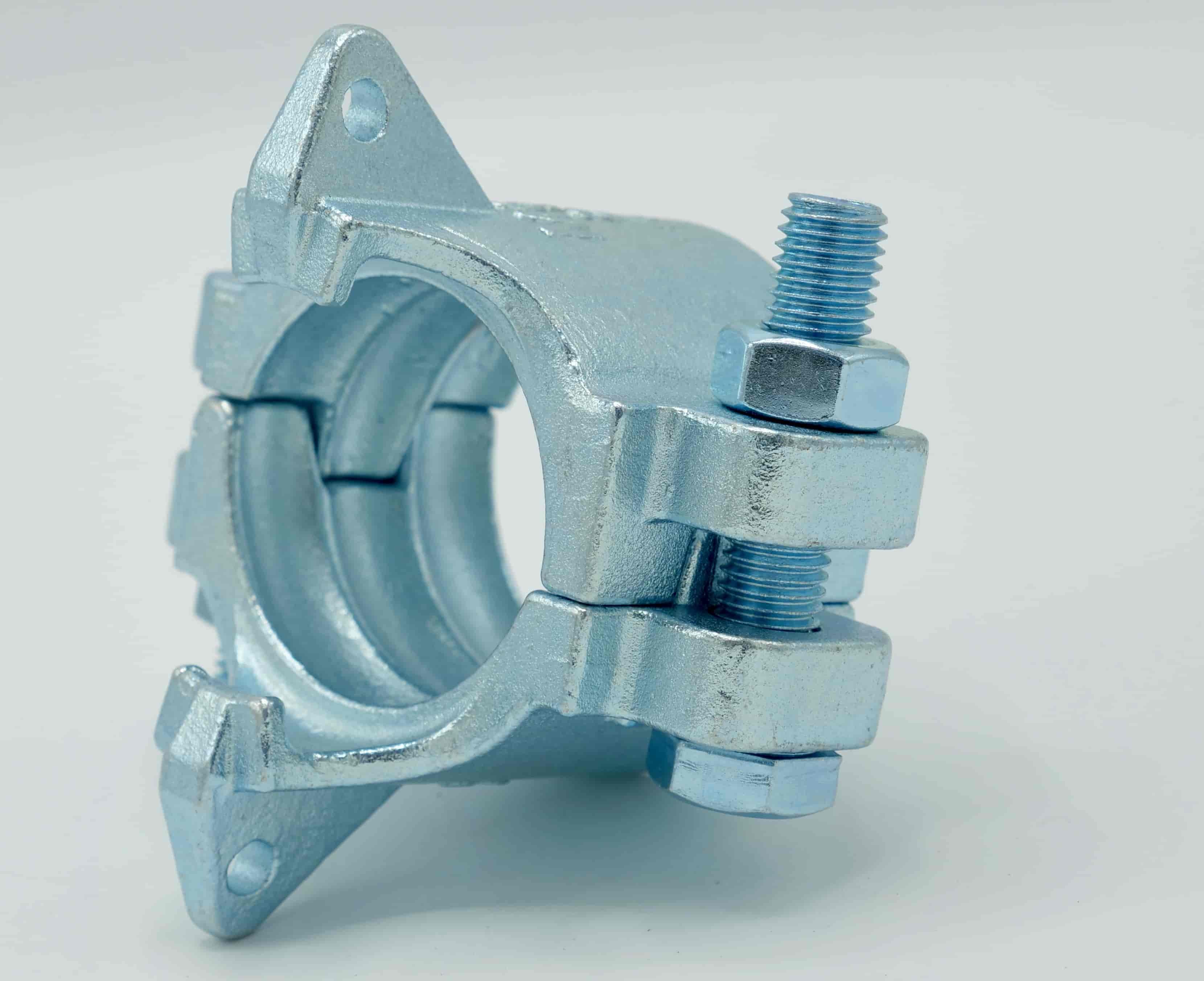

MCC Claw Clamps

Designed specifically for the Australian Mining Industry, the MCC Claw Clamps are designed to engage with the retaining ring positioned on the Claw Coupling hose tail to help prevent unintentional separation of hose clamp and tail.

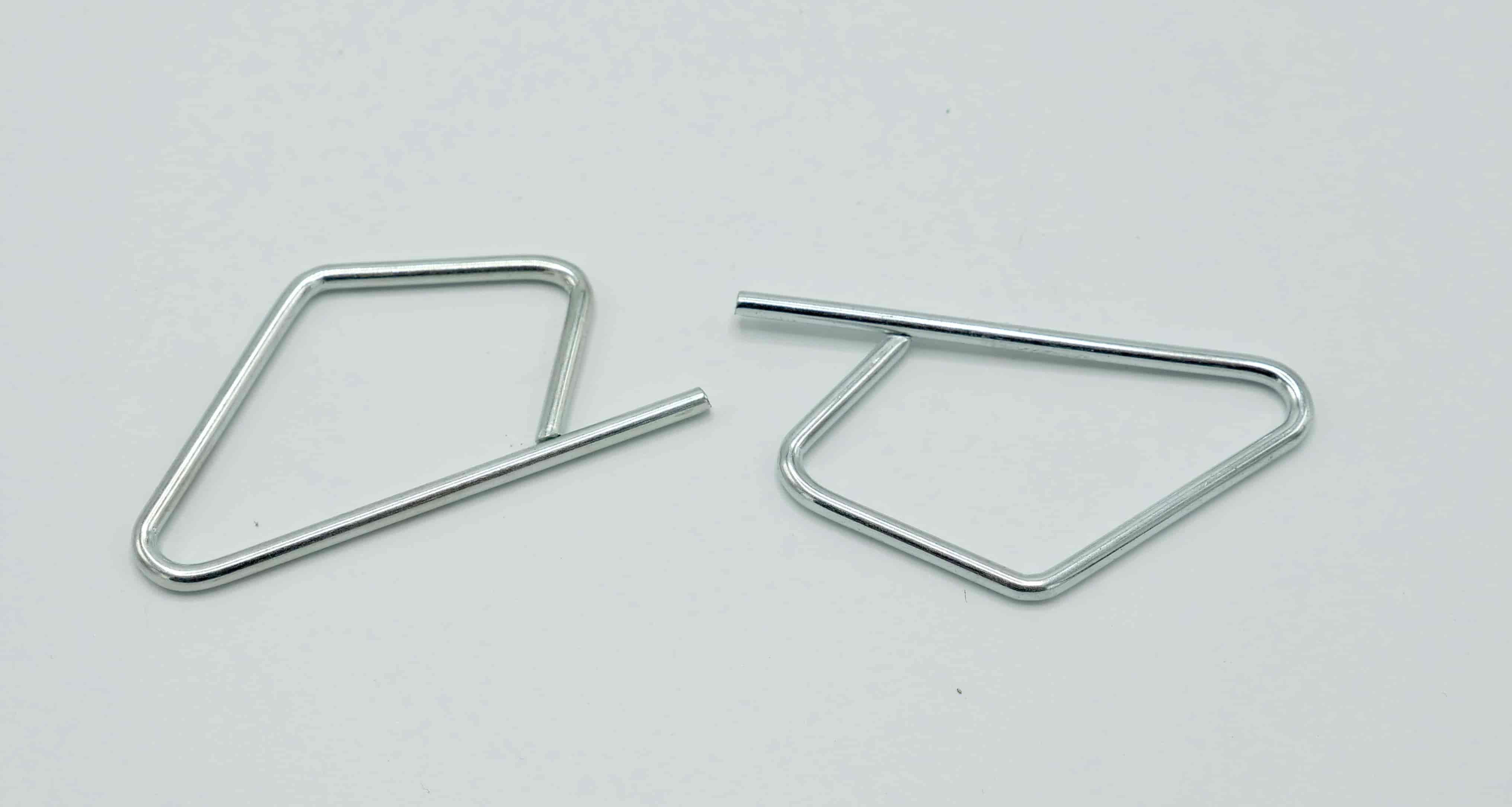

Safety Locking Pins

Diamond shape clip universally used to prevent claw couplings from unintentional disengagement. The clips are also used for hanging vent bag, tag in / tag out, key rings and many more useful applications.

Brass Gate Valve

Dezincification-Resistant (DR) Brass Gate Valve Watermark approved for potable water environments. Full flow and 100% pressure tested provides peace of mind and maximum efficiency. Available in sizes 15mm (1/2") to 100mm (4"). Tested & certified to AS 1628. Maximum pressure rating: 2500KPa.

Centre Punch Hose Clamp - CP Series

Centre punch clamps are used in conjunction with a centre punch tool; they provide a secure, quick and easy installation method for on-site "non-critical application" repairs (NOT for use with steam, large bore air hoses, hazardous gases, or other critical applications)They offer a Smooth Seal I.D. which is designed for use on all hoses, including thin walled layflat style hose, as they ensure a 360° closure around the hose being clamped.

Centre Punch Tool

MCC - MT3006 Centre Punch Tool to be used with 5/8″ wide centre punch style clamps. Ratchet action tensioning tool for applying centre punch (CP Series) clamps with a centre punch lock.

Hose Restraint (Whipcheck style)

Flexible hoses under high pressure can be found in many different industries and can contain various substances. The risk of injury from hose whip is greatest with high pressure or liquefied gases due to the rapid change in pressure resulting from a failure (for example, compressor air hoses, gas cylinder manifold connections and tanker hoses). If an unsecured pressurised hose disconnects, it will typically whip or flail in an uncontrolled manner until the system is depressurised. This situation can create a serious risk of injury or death to persons within the radius of the whipping hose.

Brass Camlock

Brass Camlocks have excellent corrosive resistance against water, hydraulic oil, coolants, gasoline and petroleum products. Thanks to its non-sparking feature, brass camlocks can be used in some special places such as underground coal mines and marine fueling applications. Brass cam lock fittings come into size from 1/2" to 6". The fittings are interchangeable with MIL SPEC MIL-C-27487/ A-A-59326 except 1/2" and 8", which have no international specifications. Working temperature for brass couplings is rated from -100°C to +230°C. Always make sure the gasket material is compatible with the media.

Both brass and stainless steel camlock fittings have good corrosive resistance, high tensile strength and durability. However, brass coupling is less expensive than stainless steel, and softer and easier to thread.

Application: Brass camlocks are normally used in low pressure suction or discharge hoses of pump, tank, IBC and other places where quick connect/disconnect is necessary like paints & inks industry. Before installation, always make sure the material is compatible with the media.

Note: All types of brass camlocks are NOT for use with compressed air or gases.

Hydraulic Flat Face Quick Coupling - ISO 16028

Flat-Face couplings with real maximum working pressure of 35 MPa and Zinc-Nickel plating. Flat valve shut-off system contributes to prevent contamination and spillage. ISO 16028 interchange. Size 1/8" has surface treatment in Mate 500 (CrIII) and it is not ISO interchangeable.

Muff Couplings

High strength gravity cast aluminium available in 3″ to 8″. Gravity casting muff couplings offer a higher amount of strength when compared to the same alloy cast in sand. Manufactured using an iron permanent mould provides greater tolerance control to that of sand cast equivalents.

To suit Table D. We have elongated the bolt holes to allow for more flexibility when fitting